Page 20 - ChipScale_Sep-Oct_2020-digital

P. 20

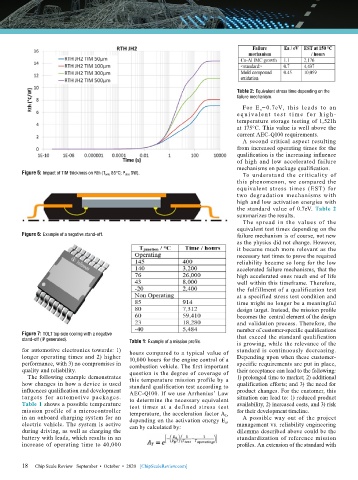

Table 2: Equivalent stress time depending on the

failure mechanism.

For E a = 0.7eV, t h is lead s to a n

e q u i v a l e n t t e s t t i m e f o r h i g h -

temperature storage testing of 1,521h

at 175°C. This value is well above the

current AEC-Q100 requirements.

A second critical aspect resulting

from increased operating times for the

qualification is the increasing influence

of high and low accelerated failure

mechanisms on package qualification.

Figure 5: Impact of TIM thickness on Rth (T amb 85°C; P diss 5W). To understand the criticality of

this phenomenon, we compared the

equivalent stress times (EST) for

two degradation mechanisms with

high and low activation energies with

the standard value of 0.7eV. Table 2

summarizes the results.

The spread in the values of the

equivalent test times depending on the

Figure 6: Example of a negative stand-off. failure mechanism is of course, not new

as the physics did not change. However,

it became much more relevant as the

necessary test times to prove the required

reliability became so long for the low

accelerated failure mechanisms, that the

high accelerated ones reach end of life

well within this timeframe. Therefore,

the fulfillment of a qualification test

at a specified stress test condition and

time might no longer be a meaningful

design target. Instead, the mission profile

becomes the central element of the design

and validation process. Therefore, the

number of customer-specific qualifications

Figure 7: TOLT top side cooling with a negative that exceed the standard qualification

stand-off (IP generated). Table 1: Example of a mission profile. is growing, while the relevance of the

for automotive electronics towards: 1) hours compared to a typical value of standard is continuously decreasing.

longer operating times and 2) higher 10,000 hours for the engine control of a Depending upon when these customer-

performance, with 3) no compromises in combustion vehicle. The first important specific requirements are put in place,

quality and reliability. question is the degree of coverage of their acceptance can lead to the following:

The following example demonstrates this temperature mission profile by a 1) prolonged time to market; 2) additional

how changes in how a device is used standard qualification test according to qualification efforts; and 3) the need for

influences qualification and development AEC-Q100. If we use Arrhenius’ Law product changes. For the customer, this

targets for automotive packages. to determine the necessary equivalent situation can lead to: 1) reduced product

Table 1 shows a possible temperature test times at a defined stress test availability, 2) increased costs, and 3) risk

mission profile of a microcontroller temperature, the acceleration factor A T , for their development timeline.

in an onboard charging system for an depending on the activation energy E a , A possible way out of the project

electric vehicle. The system is active can by calculated by: management vs. reliability engineering

during driving, as well as charging the dilemma described above could be the

battery with leads, which results in an standardization of reference mission

increase of operating time to 40,000 profiles. An extension of the standard with

18

18 Chip Scale Review September • October • 2020 [ChipScaleReview.com]