Page 15 - Chip Scale Review_July August_2023-digital

P. 15

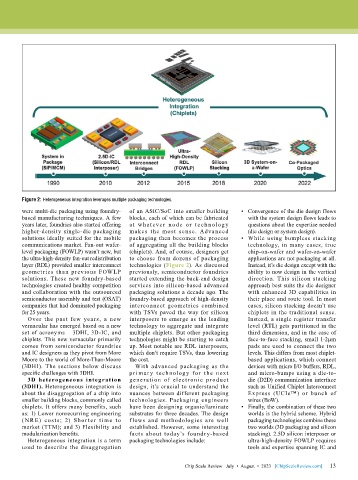

Figure 2: Heterogeneous integration leverages multiple packaging technologies.

were multi-die packaging using foundry- of an ASIC/SoC into smaller building • Convergence of the die design flows

based manufacturing techniques. A few blocks, each of which can be fabricated with the system design flows leads to

years later, foundries also started offering at what eve r node or t e ch nolog y questions about the expertise needed

higher-density single-die packaging makes the most sense. Advanced (die design or system design).

solutions ideally suited for the mobile packaging then becomes the process • While using bumpless stacking

communications market. Fan-out wafer- of aggregating all the building blocks technology, in many cases, true

level packaging (FOWLP) wasn’t new, but (chiplets). And, of course, designers get chip-on-wafer and wafer-on-wafer

the ultra-high-density fan-out redistribution to choose from dozens of packaging applications are not packaging at all.

layer (RDL) provided smaller interconnect technologies (Figure 2). As discussed Instead, it’s die design except with the

geometries than previous FOWLP previously, semiconductor foundries ability to now design in the vertical

solutions. These new foundry-based started extending the back-end design direction. This silicon stacking

technologies created healthy competition services into silicon-based advanced approach best suits the die designer

and collaboration with the outsourced packaging solutions a decade ago. The with enhanced 3D capabilities in

semiconductor assembly and test (OSAT) foundry-based approach of high-density their place and route tool. In most

companies that had dominated packaging interconnect geometries combined cases, silicon stacking doesn’t use

for 25 years. with TSVs paved the way for silicon chiplets in the traditional sense.

Over the past few years, a new interposers to emerge as the leading Instead, a single register transfer

vernacular has emerged based on a new technology to aggregate and integrate level (RTL) gets partitioned in the

set of acronyms – 3DHI, 3D-IC, and multiple chiplets. But other packaging third dimension, and in the case of

chiplets. This new vernacular primarily technologies might be starting to catch face-to-face stacking, small 1-2µm

comes from semiconductor foundries up. Most notable are RDL interposers, pads are used to connect the two

and IC designers as they pivot from More which don’t require TSVs, thus lowering levels. This differs from most chiplet-

Moore to the world of More-Than-Moore the cost. based applications, which connect

(3DHI). The sections below discuss With advanced packaging as the devices with micro I/O buffers, RDL,

specific challenges with 3DHI. pr imar y tech nolog y for the next and micro-bumps using a die-to-

3D heterogeneous integration generation of elect ronic product die (D2D) communication interface

(3DHI). Heterogeneous integration is design, it’s crucial to understand the such as Unified Chiplet Interconnect

about the disaggregation of a chip into nuances between different packaging Express (UCIe™) or bunch of

smaller building blocks, commonly called technologies. Packaging engineers wires (BoW).

chiplets. It offers many benefits, such have been designing organic/laminate • Finally, the combination of these two

as: 1) Lower nonrecurring engineering substrates for three decades. The design worlds is the hybrid scheme. Hybrid

( N R E) costs; 2) Shor ter t i me to f lows and methodologies are well packaging technologies combine these

market (TTM); and 3) Flexibility and established. However, some interesting two worlds (3D packaging and silicon

modularization benefits. facts about today’s foundry-based stacking). 2.5D silicon interposer or

Heterogeneous integration is a term packaging technologies include: ultra-high-density FOWLP requires

used to describe the disaggregation tools and expertise spanning IC and

13

Chip Scale Review July • August • 2023 [ChipScaleReview.com] 13