Page 43 - Chip Scale Review_March April_2023-digital

P. 43

Wafer-scale integration for graphene-based

optoelectronics, sensors, and imaging devices

By Souvik Ghosh [imec vzw], Amaia Zurutuza [Graphenea], Alice Guerrero [Brewer Science]

T he dawn of the 21 century be obtained via electrochemical spalling surface because of its low C solubility,

st

kick-started an era of two-

dimensional (2D) materials, of graphitic membranes in solution. Both facilitating monolayer, and even bilayer

techniques facilitate easy and selective access

graphene growth control.

with graphene in the forefront. Graphene to surface and edges of the nanosheets, Additionally, research is ongoing to

is the most well-known 2D material thereby promoting nanodecoration enable graphene growth on rigid template

and is often being referred to as the and targeted functionalization of these wafers. If Cu is sputtered directly on Si/

“wonder material.” The exceptional nanosheets. Despite being a robust technique SiO 2 wafers followed by graphene growth,

properties of graphene, such as very high to manufacture graphene sheets, mechanical the resultant SLG quality is relatively

carrier mobilities and ballistic transport, and electrochemical exfoliations remain poor due to the polycrystalline nature

promise a host of applications that range a challenging approach to enable fab and small grain structure of the Cu layer

from sensors, optical modulators, and integration. The inherently small size of (see Figure 1). Metal epitaxy on template

detectors to rapid-scan imagers, thermal graphene flakes and the lack of control over wafers such as sapphire can provide a

management, and even room-temperature the number of layers during graphene flake single catalyst orientation and ideally a

graphene-based spintronic devices. An synthesis make it very difficult to position single-crystalline SLG is grown. In this

interesting property of graphene is its these flakes accurately on a target wafer. respect, epitaxial graphene growth has

linear energy-momentum dispersion that The most promising graphene growth been demonstrated on epitaxial Cu(111)/

enables light absorption from the ultraviolet route is via chemical vapor deposition (CVD). sapphire(0001) wafers, but also other wafer

to the terahertz regime. This extreme In fact, soon after Geim and Novoselov’s types like Ge(110) can be used for epitaxial

broadband capability is a unique material mechanical exfoliation method, CVD quickly graphene growth. The latter one is not

property and makes it very interesting for caught up to enable large-scale controlled straightforward because the process window

on-chip optical communication because SLG synthesis. There are numerous catalyst to grow high-quality graphene is rather small

information can be multiplexed over a substrates available that enable high-quality but avoids transition metal contamination

wider range of wavelengths and enable graphene growth. These substrates include issues during graphene integration.

ultrafast communication. transition metal foils such as Cu, Ni, Fe, Pt, Graphene growth on a thin epitaxial Ge layer

The most high-end graphene-based and even alloys. Cu or alloys like CuNi are is also very complicated because of diffusion

applications (i.e., optical I/O devices), though interesting due to their favorable catalytic of Si into the Ge layer, which increases the

in active development at laboratory scale, properties, low C solubility and relatively roughness of the Ge layer. Nevertheless,

will need at least another decade to come low cost. The governing graphene growth because SLG growth on epitaxial surfaces

to the market simply due to limitations of mechanism relies on dissolution of the C can follow a preferred orientation, this

scalability, yield, and performance metrics species and subsequent saturation of the growth route is expected to give the highest

[1]. In the near term, single-layer-graphene surface. Cu remains an interesting catalyst graphene quality due to the absence of grain

(SLG) is already seeing an increase in

market opportunities mainly in the field

of (low-cost) sensors. These applications

will be enabled by the development of new

graphene growth and transfer techniques.

This article summarizes the near and

long-term outlook using the practical

benefits of graphene in view of its time-to-

market. Further, the specific technological

support structure needed to consider the

material as a viable option to be compatible

with existing semiconductor fabrication

infrastructure will also be outlined.

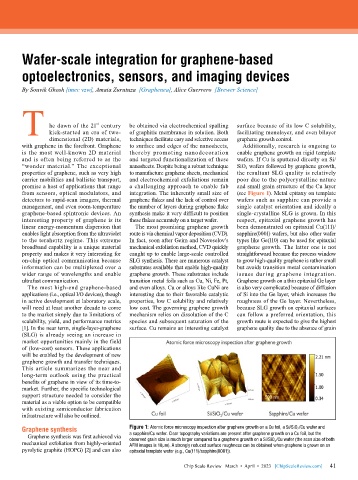

Graphene synthesis Figure 1: Atomic force microscopy inspection after graphene growth on a Cu foil, a Si/SiO 2 /Cu wafer and

Graphene synthesis was first achieved via a sapphire/Cu wafer. Clear topography variations are present after graphene growth on a Cu foil, but the

mechanical exfoliation from highly-oriented observed grain size is much larger compared to a graphene growth on a Si/SiO 2 /Cu wafer (the scan size of both

AFM images is 10μm). A strongly reduced surface roughness can be obtained when graphene is grown on an

pyrolytic graphite (HOPG) [2] and can also epitaxial template wafer (e.g., Cu(111)/sapphire(0001)).

41

Chip Scale Review March • April • 2023 [ChipScaleReview.com] 41