Page 40 - Chip Scale Review_January February_2023-digital

P. 40

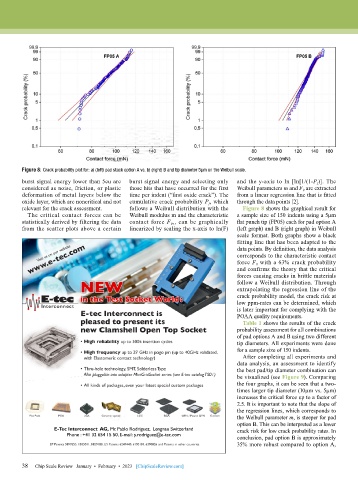

Figure 8: Crack probability plot for: a) (left) pad stack option A vs. b) (right) B and tip diameter 5µm on the Weibull scale.

burst signal energy lower than 5eu are burst signal energy and selecting only and the y-axis to ln [ln[1/(1-P f )]. The

considered as noise, friction, or plastic those hits that have occurred for the first Weibull parameters m and F 0 are extracted

deformation of metal layers below the time per indent (“first oxide crack”). The from a linear regression line that is fitted

oxide layer, which are noncritical and not cumulative crack probability P f , which through the data points [2].

relevant for the crack assessment. follows a Weibull distribution with the Figure 8 shows the graphical result for

The critical contact forces can be Weibull modulus m and the characteristic a sample size of 150 indents using a 5µm

statistically derived by filtering the data contact force F 0 ,, can be graphically flat punch tip (FP05) each for pad option A

from the scatter plots above a certain linearized by scaling the x-axis to ln(F) (left graph) and B (right graph) in Weibull

scale format. Both graphs show a black

fitting line that has been adapted to the

data points. By definition, the data analysis

corresponds to the characteristic contact

force F 0 with a 63% crack probability

and confirms the theory that the critical

forces causing cracks in brittle materials

follow a Weibull distribution. Through

extrapolating the regression line of the

crack probability model, the crack risk at

low ppm-rates can be determined, which

is later important for complying with the

POAA quality requirements.

Table 1 shows the results of the crack

probability assessment for all combinations

of pad options A and B using two different

tip diameters. All experiments were done

for a sample size of 150 indents.

After completing all experiments and

data analysis, an assessment to identify

the best pad/tip diameter combination can

be visualized (see Figure 9). Comparing

the four graphs, it can be seen that a two-

times larger tip diameter (10µm vs. 5µm)

increases the critical force up to a factor of

2.5. It is important to note that the slope of

the regression lines, which corresponds to

the Weibull parameter m, is steeper for pad

option B. This can be interpreted as a lower

E-Tec Interconnect AG, Mr. Pablo Rodriguez, Lengnau Switzerland crack risk for low crack probability rates. In

Phone : +41 32 654 15 50, E-mail: p.rodriguez@e-tec.com conclusion, pad option B is approximately

35% more robust compared to option A,

38

38 Chip Scale Review January • February • 2023 [ChipScaleReview.com]