Page 16 - Chip Scale Review_November December_2022-digital

P. 16

The displacement around 90μm from

the initial location at 25ºC to the high

temperature of 105ºC is even greater

than the diameter of the size of the

micro-bump at approximately 70µm,

which easily causes contact instability.

I n con side r at ion of t he t he r m al

expansion effect, two separate double-

sided probe heads were designed so

they could be adjusted to accurate

positions by use of fiducial markers and

precision guide pins during assembly.

However, this design still requires

optical re-alignment to check the

precision of the final position at each

testing temperature point to ensure

contact stability and repeatability.

Probe head/thermal control. The

high-speed and fine-pitch probe head

integrated with a high-performance

thermal control system is the most

critical design module of the double-

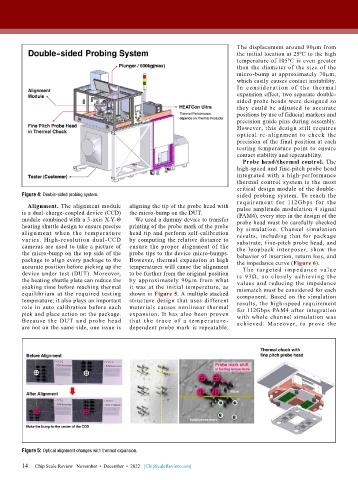

Figure 4: Double-sided probing system. sided probing system. To reach the

requirement for 112Gbps for the

Alignment. The alignment module aligning the tip of the probe head with pulse amplitude modulation 4 signal

is a dual-charge-coupled device (CCD) the micro-bump on the DUT. (PAM4), every step in the design of the

module combined with a 3-axis X-Y-Θ We used a dummy device to transfer probe head must be carefully checked

heating shuttle design to ensure precise printing of the probe mark of the probe by simulation. Channel simulation

alig n ment when the temperat u re head tip and perform self-calibration results, including that for package

varies. High-resolution dual-CCD by computing the relative distance to substrate, fine-pitch probe head, and

cameras are used to take a picture of ensure the proper alignment of the the loopback interposer, show the

the micro-bump on the top side of the probe tips to the device micro-bumps. behavior of insertion, return loss, and

package to align every package to the However, thermal expansion at high the impedance curve (Figure 6).

accurate position before picking up the temperatures will cause the alignment T he t a rgeted i mped a nce value

device under test (DUT). Moreover, to be further from the original position is 93Ω, so closely achieving the

the heating shuttle plate can reduce the by approximately 90µm from what values and reducing the impedance

soaking time before reaching thermal it was at the initial temperature, as mismatch must be considered for each

equilibrium at the required testing shown in Figure 5. A multiple stacked component. Based on the simulation

temperature; it also plays an important structure design that uses different results, the high-speed requirement

role in auto calibration before each materials causes nonlinear thermal for 112Gbps PAM4 after integration

pick and place action on the package. expansion. It has also been proven with whole channel simulation was

Because the DUT and probe head that the t race of a temperat u re - achieved. Moreover, to prove the

are not on the same side, one issue is dependent probe mark is repeatable.

Figure 5: Optical alignment changes with thermal expansion.

14

14 Chip Scale Review November • December • 2022 [ChipScaleReview.com]