Page 11 - ChipScale_Mar-Apr_2020-digital

P. 11

TECHNOLOGY TRENDS

EV Group takes on maskless lithography for

MEMS and advanced packaging

CSR asked Paul Lindner, Executive Technology Director at EV Group, to comment on the company’s

developments in maskless lithography.

CSR: EVG is using maskless lithography in lithography triggered our development wafers in advanced packaging, where epoxy

to address future back-end lithography of the maskless exposure technology materials or carrier-mounted thin wafers for

needs for advanced packaging and (MLE™) to meet critical requirements of interposers add up to several millimeters of

microelectromechanical systems (MEMS), design flexibility and minimal development bowing and warp variation. Handling such

among other applications. What is it about cycles in the high-volume-manufacturing wafers needs adaptable equipment handling

these applications that drove the design of (HVM) world by eliminating mask-related platforms (see Figure 1). In MEMS, on

your company’s technology? difficulties and costs. The new technology the other hand, topography patterning is a

EVG: A very exciting development in the enables high-resolution (<2µm L/S), stitch- frequent requirement. In both cases, MLE

overall semiconductor industry is the shift free, mask-free exposure of the entire design features permit the patterning with

toward 3D integration and heterogeneous substrate surface with high throughput and less than 2µm feature sizes.

integration within advanced packaging. low cost of ownership (CoO).

Mobile processors have triggered a CSR: Some of the future challenges for

first growth cycle in 3D/heterogeneous CSR: You have pointed out that the back-end lithography are short development

integration. We expect this growth cycle to technology is highly scalable. How so? cycles and immediate ramp up from R&D

continue as high-performance applications EVG: The system scales according to to HVM. Please flesh out the details about

such as artificial intelligence and 5G gain user needs by adding or removing ultraviolet the challenges related to immediate ramp-

traction in mobile devices, but also due (UV) exposure heads in order to facilitate up. For example, how is this future challenge

to other megatrends such as the Internet rapid transition from R&D to HVM mode, substantially different from previous time-

of Things. All of these trends facilitate optimize throughput, as well as adapt to to-market drivers?

advanced packaging, demanding new different substrate sizes and materials. MLE EVG: The flexibility of MLE allows

manufacturing technologies to support achieves the same patterning performance users to achieve faster innovation cycles

greater flexibility for varying designs, to regardless of photoresist due to a flexible and faster time to market using the same

increase performance and to lower the and scalable high-power UV laser source technology in development as later on in

system design cost. Lithography in particular that offers multiple wavelength exposure high-volume production. The technology

is demanding greater flexibility in terms options. This makes it ideal for processing employs clustered multi-wavelength laser

of needing to address local alignment a variety of substrates from small silicon or light sources operating at 375nm and/or

variations and non-linear shrinkage, to name compound semiconductor wafers to panel 405nm wavelengths. This, in turn, enables

a few requirements for molded wafers. At the sizes. While wafer specifications for fan-in thin-resist patterning, including positive and

same time, interconnect bandwidth demands packaging are rather standardized with low negative resists, polyimides, dry-film resists

denser lines and spaces. These challenges variations, this is not the case anymore for and printed circuit board (PCB) patterning.

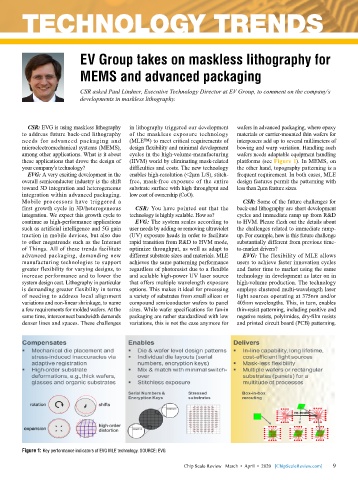

Figure 1: Key performance indicators of EVG MLE technology. SOURCE: EVG

Chip Scale Review March • April • 2020 [ChipScaleReview.com] 9 9