Page 68 - Chip Scale Review_November December_2021-digital

P. 68

exceed 250,000. Such levels of validation perform the critical checks noted above with packaging design tools. Typically,

and verification are commonplace in chip exists today, it has to be integrated into the required checks fall into two

design but are a new phenomenon for the package design flow and process. categories: physical (geometric) and

package designers. Ideally, it also must be capable of electrical connectivity.

Although the technology needed to providing results that can be displayed Physical verification of FOWLP

designs must address the unique physical

characteristics of these packages, including

the presence of multiple components,

non-Manhattan shapes, and disparate file

standards. Fortunately, FOWLP designers

do not need to check every geometry in

every die. Each individual die in a FOWLP

package is already taped out for its target

foundry with respect to DRC and LVS

comparisons. FOWLP verification does

require designers to check the interactions

between the dies, which may require

extracting several layers within each die

to see what their impacts are on each other

Figure 4: Two-step FOWLP physical verification process. and on the full package.

Regardless of the configuration, the

verification tool must understand the

layering per die and per placement,

including the ability to distinguish

between two die with the same layer

name. The key inputs for this sign-

off verification are the definition of the

assembly stack-up of the components and

the reference LVS source-system netlist.

As shown in Figure 4, the typical

FOWLP physical verification process is

to validate individual components (die,

interposer, package) separately using

their process-specific requirements, and

then define and check the 3D assembly of

the interfaces between the components,

preferably using a single rule deck or

assembly design kit (ADK). For LVL

verification, the focus is on analyzing

and verifying alignment, scaling, and

overlaps between devices and substrates,

Figure 5: LVL checking of die to interposer. as shown in Figure 5.

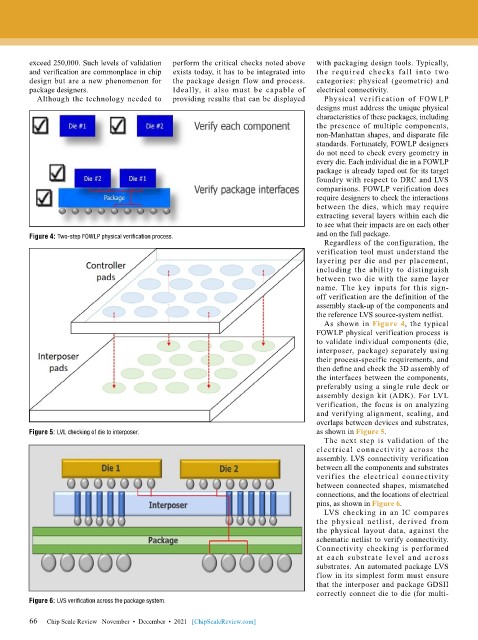

The next step is validation of the

electrical connectivity across the

assembly. LVS connectivity verification

between all the components and substrates

verifies the electrical connectivity

between connected shapes, mismatched

connections, and the locations of electrical

pins, as shown in Figure 6.

LVS checking in an IC compares

the physical netlist, derived from

the physical layout data, against the

schematic netlist to verify connectivity.

Connectivity checking is performed

at each substrate level and across

substrates. An automated package LVS

flow in its simplest form must ensure

that the interposer and package GDSII

correctly connect die to die (for multi-

Figure 6: LVS verification across the package system.

66

66 Chip Scale Review November • December • 2021 [ChipScaleReview.com]