Page 20 - ChipScale_Jan-Feb_2020-digital

P. 20

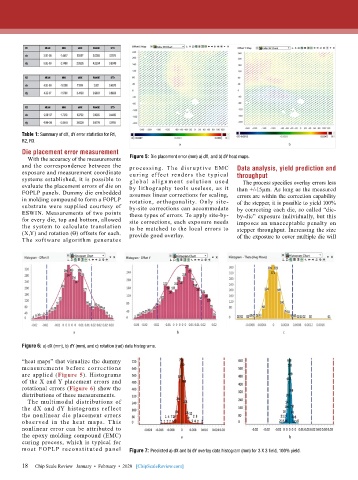

Table 1: Summary of dX, dY error statistics for R1,

R2, R3.

Die placement error measurement

With the accuracy of the measurements Figure 5: Die placement error (mm) a) dX, and b) dY heat maps.

and the correspondence between the processing. T he disr uptive EMC Data analysis, yield prediction and

exposure and measurement coordinate curing effect renders the ty pical

systems established, it is possible to g lob a l a l ig n m e nt s olut io n u s e d throughput

evaluate the placement errors of die on by lithography tools useless, as it The process specifies overlay errors less

FOPLP panels. Dummy die embedded assumes linear corrections for scaling, than +/-15µm. As long as the measured

in molding compound to form a FOPLP rotation, orthogonality. Only site- errors are within the correction capability

substrate were supplied courtesy of by-site corrections can accommodate of the stepper, it is possible to yield 100%

ESWIN. Measurements of two points these types of errors. To apply site-by- by correcting each die, so called “die-

for every die, top and bottom, allowed site corrections, each exposure needs by-die” exposure individually, but this

the system to calculate translation to be matched to the local errors to imposes an unacceptable penalty on

(X,Y) and rotation (ϴ) offsets for each. provide good overlay. stepper throughput. Increasing the size

The software algorithm generates of the exposure to cover multiple die will

Figure 6: a) dX (mm), b) dY (mm), and c) rotation (rad) data histograms.

“heat maps” that visualize the dummy

measurements before cor rections

are applied (Figure 5). Histograms

of the X and Y placement errors and

rotational errors (Figure 6) show the

distributions of these measurements.

The multimodal distributions of

the dX and dY histograms ref lect

the nonlinear die placement errors

obser ved in the heat maps. T his

nonlinear error can be attributed to

the epoxy molding compound (EMC)

curing process, which is typical for

most FOPLP reconstit uted panel Figure 7: Predicted a) dX and b) dY overlay data histogram (mm) for 3 X 3 field, 100% yield.

18 Chip Scale Review January • February • 2020 [ChipScaleReview.com]

18