Page 54 - Chip Scale Review_May June_2021-digital

P. 54

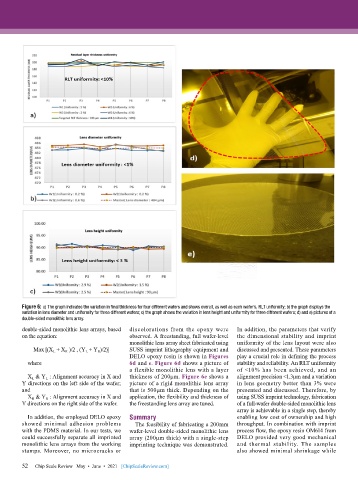

Figure 6: a) The graph indicates the variation in final thickness for four different wafers and shows overall, as well as each wafer’s, RLT uniformity; b) the graph displays the

variation in lens diameter and uniformity for three different wafers; c) the graph shows the variation in lens height and uniformity for three different wafers; d) and e) pictures of a

double-sided monolithic lens array.

double-sided monolithic lens arrays, based discolorations from the epoxy were In addition, the parameters that verify

on the equation: observed. A freestanding, full wafer-level the dimensional stability and imprint

monolithic lens array sheet fabricated using uniformity of the lens layout were also

Max [(X L + X R )/2 , (Y L + Y R )/2)] SUSS imprint lithography equipment and discussed and presented. These parameters

DELO epoxy resin is shown in Figures play a crucial role in defining the process

where 6d and e. Figure 6d shows a picture of stability and reliability. An RLT uniformity

a flexible monolithic lens with a layer of <10% has been achieved, and an

X L & Y L : Alignment accuracy in X and thickness of 200µm. Figure 6e shows a alignment precision <1.3µm and a variation

Y directions on the left side of the wafer; picture of a rigid monolithic lens array in lens geometry better than 3% were

and that is 500µm thick. Depending on the presented and discussed. Therefore, by

X R & Y R : Alignment accuracy in X and application, the flexibility and thickness of using SUSS imprint technology, fabrication

Y directions on the right side of the wafer. the freestanding lens array are tuned. of a full-wafer double-sided monolithic lens

array is achievable in a single step, thereby

In addition, the employed DELO epoxy Summary enabling low cost of ownership and high

showed minimal adhesion problems The feasibility of fabricating a 200mm throughput. In combination with imprint

with the PDMS material. In our tests, we wafer-level double-sided monolithic lens process flow, the epoxy resin OM614 from

could successfully separate all imprinted array (200µm thick) with a single-step DELO provided very good mechanical

monolithic lens arrays from the working imprinting technique was demonstrated. and thermal stability. The samples

stamps. Moreover, no microcracks or also showed minimal shrinkage while

52

52 Chip Scale Review May • June • 2021 [ChipScaleReview.com]