Page 15 - Chip Scale Review_May June_2021-digital

P. 15

MEMS impedance matching

As IC frequency increases, impedance

can also become a significant factor and

it can be a huge challenge coupling the

probe head to the next interconnect level.

However, by using impedance matching

when developing the probe head, it

is possible to achieve a transparent

transition between the tester, the PCB and

probe head, and the wafer.

This process once again begins with

the customized MEMSFlex™ probe head

stack-up and fine tuning the inductance and

capacitance. The primary goal is to achieve

a reflection loss of -20dB to -15dB with

a transmission loss of -1dB at the highest

frequency requested. Additional parameters

Figure 6: MEMS probe head guide plate stack-up examples for optimal heat dissipation. that must be considered aside from the

Figure 7: Current measurements at various test temperatures.

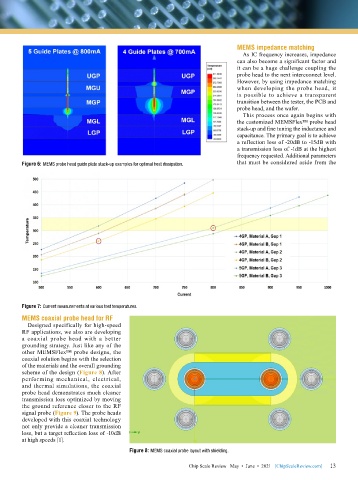

MEMS coaxial probe head for RF

Designed specifically for high-speed

RF applications, we also are developing

a coaxial probe head with a better

grounding strategy. Just like any of the

other MEMSFlex™ probe designs, the

coaxial solution begins with the selection

of the materials and the overall grounding

scheme of the design (Figure 8). After

performing mechanical, electrical,

and thermal simulations, the coaxial

probe head demonstrates much cleaner

transmission loss optimized by moving

the ground reference closer to the RF

signal probe (Figure 9). The probe heads

developed with this coaxial technology

not only provide a cleaner transmission

loss, but a target reflection loss of -10dB

at high speeds [1].

Figure 8: MEMS coaxial probe layout with shielding.

13

Chip Scale Review May • June • 2021 [ChipScaleReview.com] 13