Page 50 - ChipScale_Nov-Dec_2020-digital

P. 50

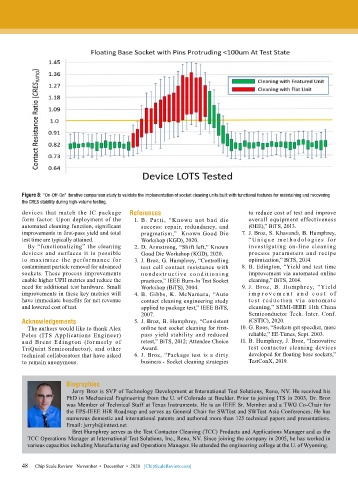

Figure 8: “On-Off-On” iterative comparison study to validate the implementation of socket cleaning units built with functional features for maintaining and recovering

the CRES stability during high-volume testing.

devices that match the IC package References to reduce cost of test and improve

form factor. Upon deployment of the 1. B. Patti, “Known not bad die overall equipment effectiveness

automated cleaning function, significant success: repair, redundancy, and (OEE),” BiTS, 2013.

improvements in first-pass yield and total pragmatism,” Known Good Die 7. J. Broz, S. Khavandi, B. Humphrey,

test time are typically attained. Workshop (KGD), 2020. “ U n i q u e m e t ho d ol o g i e s fo r

By “functionalizing” the cleaning 2. D. Armstrong, “Shift left,” Known investigating on-line cleaning

devices and surfaces it is possible Good Die Workshop (KGD), 2020. process parameters and recipe

to maximize the performance for 3. J. Broz, G. Humphrey, “Controlling optimization,” BiTS, 2014.

contaminant particle removal for advanced test cell contact resistance with 8. B. Edington, “Yield and test time

sockets. These process improvements nondest r uct ive cond it ion i ng improvement via automated online

enable higher UPH metrics and reduce the practices,” IEEE Burn-In Test Socket cleaning,” BiTS, 2014.

need for additional test hardware. Small Workshop (BiTS), 2004. 9. J. Broz, B. Humphrey, “Yield

improvements in these key metrics will 4. B. Gibbs, K. McNamara, “Auto i m p r o v e m e n t a n d c o s t o f

have immediate benefits for net revenue contact cleaning engineering study t e s t r e d u c t ion v ia aut om at e

and lowered cost of test. applied to package test,” IEEE BiTS, cleaning,” SEMI-IEEE 11th China

2007. Semiconductor Tech. Inter. Conf.

Acknowledgements 5. J. Broz, B. Humphrey, “Consistent (CSTIC), 2020.

The authors would like to thank Alex online test socket cleaning for first- 10. G. Roos, “Sockets get speedier, more

Poles (ITS Applications Engineer) pass yield stability and reduced reliable,” EE-Times, Sept. 2003.

and Brent Edington (for merly of retest,” BiTS, 2012; Attendee Choice 11. B. Humphrey, J. Broz, “Innovative

TriQuint Semiconductor), and other Award. test contactor cleaning devices

technical collaborators that have asked 6. J. Broz, “Package test is a dirty developed for floating base sockets,”

to remain anonymous. business - Socket cleaning strategies TestConX, 2019.

Biographies

Jerry Broz is SVP of Technology Development at International Test Solutions, Reno, NV. He received his

PhD in Mechanical Engineering from the U. of Colorado at Boulder. Prior to joining ITS in 2003, Dr. Broz

was Member of Technical Staff at Texas Instruments. He is an IEEE Sr. Member and a TWG Co-Chair for

the EPS-IEEE HiR Roadmap and serves as General Chair for SWTest and SWTest Asia Conferences. He has

numerous domestic and international patents and authored more than 125 technical papers and presentations.

Email: jerryb@inttest.net

Bret Humphrey serves as the Test Contactor Cleaning (TCC) Products and Applications Manager and as the

TCC Operations Manager at International Test Solutions, Inc., Reno, NV. Since joining the company in 2005, he has worked in

various capacities including Manufacturing and Operations Manager. He attended the engineering college at the U. of Wyoming.

48 Chip Scale Review November • December • 2020 [ChipScaleReview.com]

48