Page 30 - ChipScale_Jul-Aug_2020-Digital

P. 30

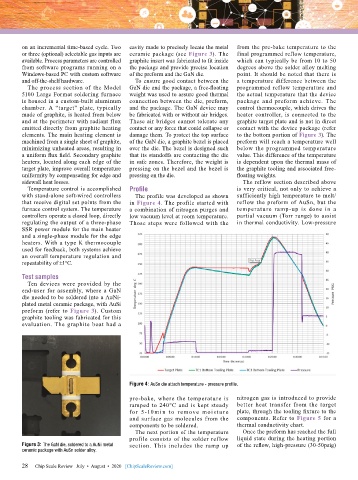

on an incremental time-based cycle. Two cavity made to precisely locate the metal from the pre-bake temperature to the

or three (optional) selectable gas inputs are ceramic package (see Figure 3). The final programmed reflow temperature,

available. Process parameters are controlled graphite insert was fabricated to fit inside which can typically be from 10 to 50

from software programs running on a the package and provide precise location degrees above the solder alloy melting

Windows-based PC with custom software of the preform and the GaN die. point. It should be noted that there is

and off-the-shelf hardware. To ensure good contact between the a temperature difference between the

The process section of the Model GaN die and the package, a free-floating programmed reflow temperature and

5100 Large Format soldering furnace weight was used to assure good thermal the actual temperature that the device

is housed in a custom-built aluminum connection between the die, preform, package and preform achieve. The

chamber. A “target” plate, typically and the package. The GaN device may control thermocouple, which drives the

made of graphite, is heated from below be fabricated with or without air bridges. heater controller, is connected to the

and at the perimeter with radiant flux These air bridges cannot tolerate any graphite target plate and is not in direct

emitted directly from graphite heating contact or any force that could collapse or contact with the device package (refer

elements. The main heating element is damage them. To protect the top surface to the bottom portion of Figure 3). The

machined from a single sheet of graphite, of the GaN die, a graphite bezel is placed preform will reach a temperature well

minimizing unheated areas, resulting in over the die. The bezel is designed such below the programmed temperature

a uniform flux field. Secondary graphite that its standoffs are contacting the die value. This difference of the temperature

heaters, located along each edge of the in safe zones. Therefore, the weight is is dependent upon the thermal mass of

target plate, improve overall temperature pressing on the bezel and the bezel is the graphite tooling and associated free-

uniformity by compensating for edge and pressing on the die. floating weights.

sidewall heat losses. The reflow section described above

Temperature control is accomplished Profile is very critical, not only to achieve a

with stand-alone soft-wired controllers The profile was developed as shown sufficiently high temperature to melt/

that receive digital set points from the in Figure 4. The profile started with reflow the preform of AuSn, but the

furnace control system. The temperature a combination of nitrogen purges and temperature ramp-up is done in a

controllers operate a closed loop, directly low vacuum level at room temperature. partial vacuum (Torr range) to assist

regulating the output of a three-phase Those steps were followed with the in thermal conductivity. Low-pressure

SSR power module for the main heater

and a single-phase module for the edge

heaters. With a type K thermocouple

used for feedback, both systems achieve

an overall temperature regulation and

repeatability of ±1°C.

Test samples

Ten devices were provided by the

end-user for assembly, where a GaN

die needed to be soldered into a AuNi-

plated metal ceramic package, with AuSi

preform (refer to Figure 3). Custom

graphite tooling was fabricated for this

evaluation. The graphite boat had a

Figure 4: AuSn die attach temperature - pressure profile.

pre-bake, where the temperature is nitrogen gas is introduced to provide

ramped to 240°C and is kept steady better heat transfer from the target

for 5-10 m i n to remove moist u re plate, through the tooling fixture to the

and surface gas molecules from the components. Refer to Figure 5 for a

components to be soldered. thermal conductivity chart.

The next portion of the temperature Once the preform has reached the full

profile consists of the solder reflow liquid state during the heating portion

Figure 3: The GaN die, soldered to a AuNi metal section. This includes the ramp up of the reflow, high-pressure (30-50psig)

ceramic package with AuSn solder alloy.

28 Chip Scale Review July • August • 2020 [ChipScaleReview.com]

28