Page 24 - ChipScale_Jul-Aug_2020-Digital

P. 24

Solder stock is supplied in three main

forms: paste, preform (freeform/pre-

applied on substrate/die backside), and

wire. Solder paste is most commonly

deployed by means of a stencil-printing

process. The solder paste must be tacky

enough to secure the components in

place throughout the production process,

especially until the reflow process.

During the ref low process, tight

control of the temperature profiles is

extremely important. The temperature

rate of increase must be slow enough to

prevent solder balling, while also being

fast enough not to deplete the flux. The

ultimate temperature needs to be as

low as possible to avoid damage, but

still high enough to fully activate the

flux, melt the solder itself, and allow

for adequate wetting. Cooling should

be quick enough to retain the desired

shape and prevent oxidation, while slow

enough to control substrate warpage.

There are several possibilities to

dispense solder wire, which can be

provided flux-less, thereby eliminating

f lux residue issues. An established

approach is to feed solder wire onto a

heated lead frame while controlling feed

rate and retraction time to achieve the

desired melt amount. A spanking tool

is then used to distribute the solder into

the desired shape and die placement

ensues (Figure 4). To improve the

process wettability, die attach systems

can suppor t the prog ram ming of

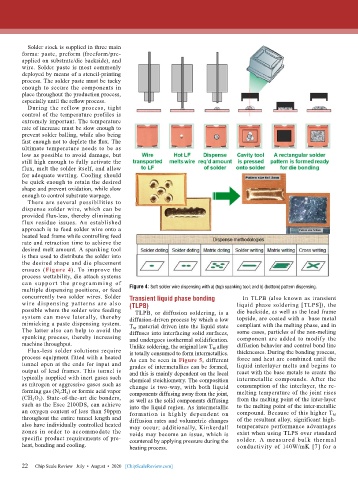

multiple dispensing positions, or feed Figure 4: Soft solder wire dispensing with a) (top) spanking tool; and b) (bottom) pattern dispensing.

concurrently two solder wires. Solder Transient liquid phase bonding In TLPB (also known as transient

wire dispensing patterns are also (TLPB) liquid phase soldering [TLPS]), the

possible where the solder wire feeding TLPB, or diffusion soldering, is a die backside, as well as the lead frame

system can move laterally, thereby diffusion-driven process by which a low topside, are coated with a base metal

mimicking a paste dispensing system. T M material driven into the liquid state compliant with the melting phase, and in

The latter also can help to avoid the diffuses into interfacing solid surfaces, some cases, particles of the non-melting

spanking process, thereby increasing and undergoes isothermal solidification. component are added to modify the

machine throughput. Unlike soldering, the original low T M alloy diffusion behavior and control bond line

Flux-less solder solutions require is totally consumed to form intermetallics. thicknesses. During the bonding process,

process equipment fitted with a heated As can be seen in Figure 5, different force and heat are combined until the

tunnel open at the ends for input and grades of intermetallics can be formed, liquid interlayer melts and begins to

output of lead frames. This tunnel is and this is mainly dependent on the local react with the base metals to create the

typically supplied with inert gases such chemical stoichiometry. The composition intermetallic compounds. After the

as nitrogen or aggressive gases such as change is two-way, with both liquid consumption of the interlayer, the re-

forming gas (N 2 :H 2 ) or formic acid vapor components diffusing away from the joint, melting temperature of the joint rises

(CH 2 O 2 ). State-of-the-art die bonders, as well as the solid components diffusing from the melting point of the inter-layer

such as the Esec 2100DS, can achieve into the liquid region. As intermetallic to the melting point of the inter-metallic

an oxygen content of less than 50ppm formation is highly dependent on compound. Because of this higher T M

throughout the entire tunnel length and diffusion rates and volumetric changes of the resultant alloy, significant high-

also have individually controlled heated may occur; additionally, Kinkerdall temperature performance advantages

zones in order to accommodate the voids may become an issue, which is exist when using TLPS over standard

specific product requirements of pre- countered by applying pressure during the solder. A measured bulk ther mal

heat, bonding and cooling. heating process. conductivity of 140W/mK [7] for a

22 Chip Scale Review July • August • 2020 [ChipScaleReview.com]

22