Page 10 - Chip Scale Review_March-April_2024-digital

P. 10

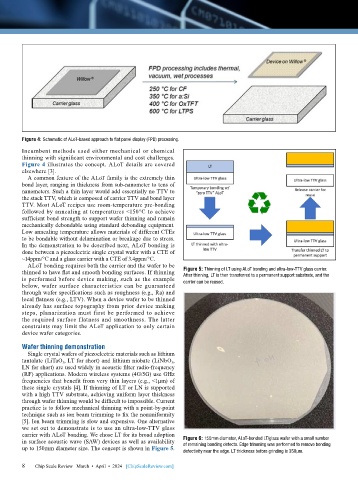

Figure 4: Schematic of ALoT-based approach to flat panel display (FPD) processing.

Incumbent methods used either mechanical or chemical

thinning with significant environmental and cost challenges.

Figure 4 illustrates the concept. ALoT details are covered

elsewhere [3].

A common feature of the ALoT family is the extremely thin

bond layer, ranging in thickness from sub-nanometer to tens of

nanometers. Such a thin layer would add essentially no TTV to

the stack TTV, which is composed of carrier TTV and bond layer

TTV. Most ALoT recipes use room-temperature pre-bonding

followed by annealing at temperatures <150°C to achieve

sufficient bond strength to support wafer thinning and remain

mechanically debondable using standard debonding equipment.

Low annealing temperature allows materials of different CTEs

to be bondable without delamination or breakage due to stress.

In the demonstration to be described next, ALoT bonding is

done between a piezoelectric single crystal wafer with a CTE of

~14ppm/°C and a glass carrier with a CTE of 3.4ppm/°C.

ALoT bonding requires both the carrier and the wafer to be

thinned to have flat and smooth bonding surfaces. If thinning Figure 5: Thinning of LT using ALoT bonding and ultra-low-TTV glass carrier.

is performed before device making, such as the example After thinning, LT is then transferred to a permanent support substrate, and the

below, wafer surface characteristics can be guaranteed carrier can be reused.

through wafer specifications such as roughness (e.g., Ra) and

local flatness (e.g., LTV). When a device wafer to be thinned

already has surface topography from prior device making

steps, planarization must first be performed to achieve

the required surface flatness and smoothness. The latter

constraints may limit the ALoT application to only certain

device wafer categories.

Wafer thinning demonstration

Single crystal wafers of piezoelectric materials such as lithium

tantalate (LiTaO 3 , LT for short) and lithium niobate (LiNbO 3 ,

LN for short) are used widely in acoustic filter radio-frequency

(RF) applications. Modern wireless systems (4G/5G) use GHz

frequencies that benefit from very thin layers (e.g., <1µm) of

these single crystals [4]. If thinning of LT or LN is supported

with a high TTV substrate, achieving uniform layer thickness

through wafer thinning would be difficult to impossible. Current

practice is to follow mechanical thinning with a point-by-point

technique such as ion beam trimming to fix the nonuniformity

[5]. Ion beam trimming is slow and expensive. One alternative

we set out to demonstrate is to use an ultra-low-TTV glass

carrier with ALoT bonding. We chose LT for its broad adoption

in surface acoustic wave (SAW) devices as well as availability Figure 6: 150mm diameter, ALoT-bonded LT/glass wafer with a small number

up to 150mm diameter size. The concept is shown in Figure 5. of remaining bonding defects. Edge trimming was performed to remove bonding

defectivity near the edge. LT thickness before grinding is 350µm.

8 8 Chip Scale Review March • April • 2024 [ChipScaleReview.com]