Page 22 - Chip Scale Review Sep Oct_2022-digital

P. 22

chemical shrinkage of the EMC, D ie s y st emat ic sh i f t . D u r i ng

the CTE of the carrier, gravity, the encapsulation of a die-attached substrate,

debonding process, etc. die shift may happen and can be found

• The die shift caused by the CTE after debonding of the molded substrate

mismatch between the EMC and (Figure 8). Oftentimes, the trend of die

silicon, which is also influenced by shift can be observed to be systematic.

chemical shrinkage of the EMC, the The major contributing factor is material-

type of EMC, and the thermal release related shrinkage of the carrier, adhesive

tape in use. and EMC. Fortunately, the issue can be

• The amount of die shift compensation predicted and compensation provided

that can be accomplished by using during die pick-and-place (Figure 9).

intelligent offset introduced during the Wafer substrate warpage handling

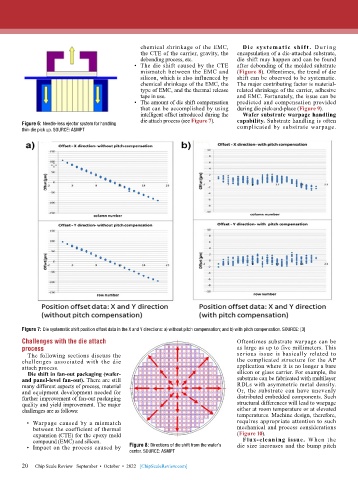

die attach process (see Figure 7). capability. Substrate handling is often

Figure 6: Needle-less ejector system for handling complicated by substrate warpage.

thin-die pick up. SOURCE: ASMPT

Figure 7: Die systematic shift position offset data in the X and Y directions: a) without pitch compensation; and b) with pitch compensation. SOURCE: [3]

Challenges with the die attach Oftentimes substrate warpage can be

process as large as up to five millimeters. This

The following sections discuss the serious issue is basically related to

challenges associated with the die the complicated structure for the AP

attach process. application where it is no longer a bare

Die shift in fan-out packaging (wafer- silicon or glass carrier. For example, the

and panel-level fan-out). There are still substrate can be fabricated with multilayer

many different aspects of process, material RDLs with asymmetric metal density.

and equipment development needed for Or, the substrate can have unevenly

further improvement of fan-out packaging distributed embedded components. Such

quality and yield improvement. The major structural differences will lead to warpage

challenges are as follows: either at room temperature or at elevated

temperatures. Machine design, therefore,

• Warpage caused by a mismatch requires appropriate attention to such

between the coefficient of thermal mechanical and process considerations

expansion (CTE) for the epoxy mold (Figure 10).

compound (EMC) and silicon. Flux-cleaning issue. When the

• Impact on the process caused by Figure 8: Directions of die shift from the wafer’s die size increases and the bump pitch

center. SOURCE: ASMPT

20

20 Chip Scale Review September • October • 2022 [ChipScaleReview.com]