Page 54 - Chip Scale Review_January February_2022-digital

P. 54

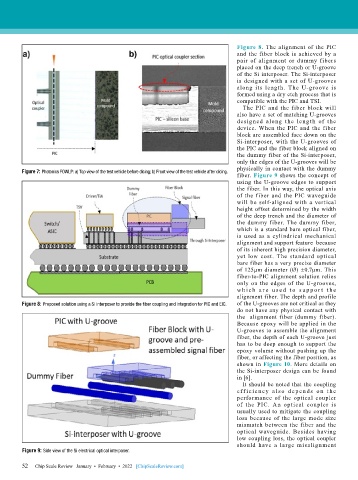

Figure 8. The alignment of the PIC

and the fiber block is achieved by a

pair of alignment or dummy fibers

placed on the deep trench or U-groove

of the Si interposer. The Si-interposer

is designed with a set of U-grooves

along its length. The U-groove is

formed using a dry etch process that is

compatible with the PIC and TSI.

The PIC and the fiber block will

also have a set of matching U-grooves

designed along the length of the

device. When the PIC and the fiber

block are assembled face down on the

Si-interposer, with the U-grooves of

the PIC and the fiber block aligned on

the dummy fiber of the Si-interposer,

only the edges of the U-grooves will be

physically in contact with the dummy

Figure 7: Photonics FOWLP: a) Top view of the test vehicle before dicing; b) Front view of the test vehicle after dicing.

fiber. Figure 9 shows the concept of

using the U-groove edges to support

the fiber. In this way, the optical axis

of the fiber and the PIC waveguide

will be self-aligned with a vertical

height offset determined by the width

of the deep trench and the diameter of

the dummy fiber. The dummy fiber,

which is a standard bare optical fiber,

is used as a cylindrical mechanical

alignment and support feature because

of its inherent high precision diameter,

yet low cost. The standard optical

bare fiber has a very precise diameter

of 125µm diameter (Ø) ±0.7μm. This

fiber-to-PIC alignment solution relies

only on the edges of the U-grooves,

w h i c h a r e u s e d t o s u p p o r t t h e

alignment fiber. The depth and profile

Figure 8: Proposed solution using a Si interposer to provide the fiber coupling and integration for PIC and EIC. of the U-grooves are not critical as they

do not have any physical contact with

the alignment fiber (dummy fiber).

Because epoxy will be applied in the

U-grooves to assemble the alignment

fiber, the depth of each U-groove just

has to be deep enough to support the

epoxy volume without pushing up the

fiber, or affecting the fiber position, as

shown in Figure 10. More details on

the Si-interposer design can be found

in [6].

It should be noted that the coupling

ef f ic ie n c y a l s o d e p e nd s o n t h e

performance of the optical coupler

of the PIC. An optical coupler is

usually used to mitigate the coupling

loss because of the large mode size

mismatch between the fiber and the

optical waveguide. Besides having

low coupling loss, the optical coupler

should have a large misalignment

Figure 9: Side view of the Si electrical optical interposer.

52

52 Chip Scale Review January • February • 2022 [ChipScaleReview.com]