Page 10 - ChipScale_Jan-Feb_2021-digital

P. 10

apply as for the smaller consider a multi-chip module that, without

part. Consider single-site left shift, requires a 520s final test for

testing of a 10nm device 72.8% yield and a 1,040s system-level test

with 85 die per wafer. for 85.4% yield. The shift left flow reduces

Assume that without manufacturing cost 28% and increases parts

using a shift-left flow, shipped by 37% (Figure 5).

this device requires a

30s wafer-probe time Test system changes

at 75% yield and a 60s For an effective shift-left strategy,

KGD test time for 87.5% test systems will require some changes.

yield. With the shift- One key point is that active thermal

left flow, manufacturing control is becoming important, and it

cost increases 16%, is something you cannot do on wafer

but unfound failures probers. With wafer probers’ chucks and

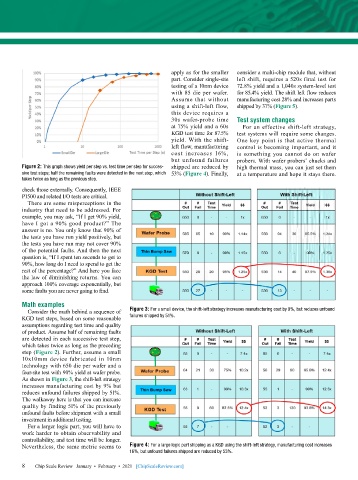

Figure 2: This graph shows yield per step vs. test time per step for succes- shipped are reduced by high thermal mass, you can just set them

sive test steps; half the remaining faults were detected in the next step, which 53% (Figure 4). Finally, at a temperature and hope it stays there.

takes twice as long as the previous step.

check those externally. Consequently, IEEE

P1500 and related I/O tests are critical.

There are some misperceptions in the

industry that need to be addressed. For

example, you may ask, “If I get 90% yield,

have I got a 90% good product?” The

answer is no. You only know that 90% of

the tests you have run yield positively, but

the tests you have run may not cover 90%

of the potential faults. And then the next

question is, “If I spent ten seconds to get to

90%, how long do I need to spend to get the

rest of the percentage?” And here you face

the law of diminishing returns. You can

approach 100% coverage exponentially, but

some faults you are never going to find.

Math examples

Consider the math behind a sequence of Figure 3: For a small device, the shift-left strategy increases manufacturing cost by 9%, but reduces unfound

KGD test steps, based on some reasonable failures shipped by 51%.

assumptions regarding test time and quality

of product. Assume half of remaining faults

are detected in each successive test step,

which takes twice as long as the preceding

step (Figure 2). Further, assume a small

10x10mm device fabricated in 10nm

technology with 650 die per wafer and a

four-site test with 90% yield at wafer probe.

As shown in Figure 3, the shift-left strategy

increases manufacturing cost by 9% but

reduces unfound failures shipped by 51%.

The walkaway here is that you can increase

quality by finding 51% of the previously

unfound faults before shipment with a small

investment in additional testing.

For a larger logic part, you will have to

work harder to obtain observability and

controllability, and test time will be longer.

Nevertheless, the same metric seems to Figure 4: For a large logic part shipping as a KGD using the shift-left strategy, manufacturing cost increases

16%, but unfound failures shipped are reduced by 53%.

8 8 Chip Scale Review January • February • 2021 [ChipScaleReview.com]