Page 61 - Chip Scale Review_March April_2022-digital

P. 61

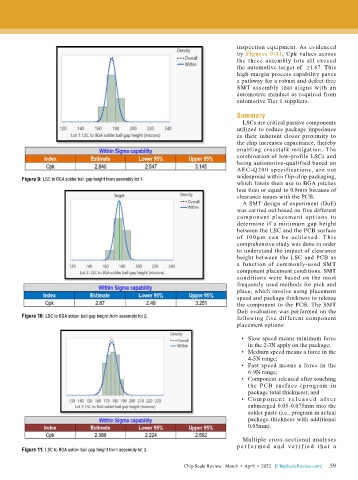

inspection equipment. As evidenced

by Figures 9-11, Cpk values across

the three assembly lots all exceed

the automotive target of ≥1.67. This

high-margin process capability paves

a pathway for a robust and defect-free

SMT assembly that aligns with an

automotive mindset as required from

automotive Tier 1 suppliers.

Summary

LSCs are critical passive components

utilized to reduce package impedance

as their inherent closer proximity to

the chip increases capacitance, thereby

enabling crosstalk mitigation. The

combination of low-profile LSCs and

being automotive-qualified based on

AEC-Q200 specifications, are not

widespread within flip-chip packaging,

Figure 9: LSC to BGA solder ball gap height from assembly lot 1.

which limits their use to BGA pitches

less than or equal to 0.8mm because of

clearance issues with the PCB.

A SMT design of experiment (DoE)

was carried out based on five different

component placement options to

determine if a minimum gap height

between the LSC and the PCB surface

of 100µm can be achieved. T his

comprehensive study was done in order

to understand the impact of clearance

height between the LSC and PCB as

a function of commonly-used SMT

component placement conditions. SMT

conditions were based on the most

frequently used methods for pick and

place, which involve using placement

speed and package thickness to release

the component to the PCB. The SMT

DoE evaluation was performed on the

Figure 10: LSC to BGA solder ball gap height from assembly lot 2. following five different component

placement options:

• Slow speed means minimum force

in the 2-3N apply on the package;

• Medium speed means a force in the

4-5N range;

• Fast speed means a force in the

6-9N range;

• Component released after touching

the PCB surface ( program in

package total thickness); and

• C o m p o n e n t r e l e a s e d a f t e r

submerged 0.05-0.075mm into the

solder paste (i.e., program in actual

package thickness with additional

0.05mm).

Multiple cross-sectional analyses

p e r f o r m e d a n d v e r i f i e d t h a t a

Figure 11: LSC to BGA solder ball gap height from assembly lot 3.

59

Chip Scale Review March • April • 2022 [ChipScaleReview.com] 59