Page 42 - Chip Scale Review_January February_2022-digital

P. 42

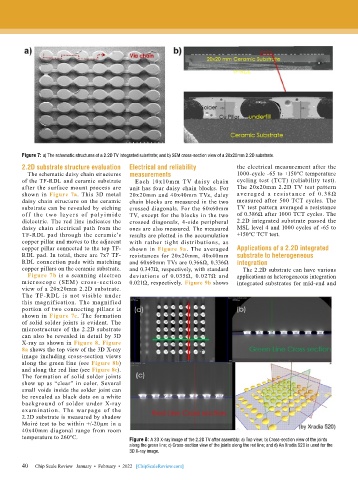

Figure 7: a) The schematic structures of a 2.2D TV integrated substrate; and b) SEM cross-section view of a 20x20mm 2.2D substrate.

2.2D substrate structure evaluation Electrical and reliability the electrical measurement after the

The schematic daisy chain structures measurements 1000-cycle -65 to +150ºC temperature

of the TF-RDL and ceramic substrate Each 10x10mm TV daisy chain cycling test (TCT) (reliability test).

after the surface mount process are unit has four daisy chain blocks. For The 20x20mm 2.2D TV test pattern

shown in Figure 7a. This 3D metal 20x20mm and 40x40mm TVs, daisy ave r a ge d a r e si s t a n c e of 0. 38 Ω

daisy chain structure on the ceramic chain blocks are measured in the two measured after 500 TCT cycles. The

substrate can be revealed by etching crossed diagonals. For the 60x60mm TV test pattern averaged a resistance

of f t he t wo laye r s of poly i m ide TV, except for the blocks in the two of 0.386Ω after 1000 TCT cycles. The

dielectric. The red line indicates the crossed diagonals, 4-side peripheral 2.2D integrated substrate passed the

daisy chain electrical path from the ones are also measured. The measured MSL level 4 and 1000 cycles of -65 to

TF-RDL pad through the ceramic’s results are plotted in the accumulation +150ºC TCT test.

copper pillar and moves to the adjacent with rather tight distributions, as

copper pillar connected to the top TF- shown in Figure 9a. The averaged Applications of a 2.2D integrated

RDL pad. In total, there are 7x7 TF- resistances for 20x20mm, 40x40mm substrate to heterogeneous

RDL connection pads with matching and 60x60mm TVs are 0.366Ω, 0.336Ω integration

copper pillars on the ceramic substrate. and 0.347Ω, respectively, with standard The 2.2D substrate can have various

Figure 7b is a scanning electron deviations of 0.035Ω, 0.027Ω and applications as heterogeneous integration

microscope (SEM) cross-section 0.021Ω, respectively. Figure 9b shows integrated substrates for mid-end and

view of a 20x20mm 2.2D substrate.

The TF-R DL is not visible under

this magnification. The magnified

portion of two connecting pillars is

shown in Figure 7c. The formation

of solid solder joints is evident. The

microstructure of the 2.2D substrate

can also be revealed in detail by 3D

X-ray as shown in Figure 8. Figure

8a shows the top view of the 3D X-ray

image including cross-section views

along the green line (see Figure 8b)

and along the red line (see Figure 8c).

The formation of solid solder joints

show up as “clear” in color. Several

small voids inside the solder joint can

be revealed as black dots on a white

background of solder under X-ray

examination. The war page of the

2.2D substrate is measured by shadow

Moiré test to be within +/-20μm in a

40x40mm diagonal range from room

temperature to 260ºC. Figure 8: A 3D X-ray image of the 2.2D TV after assembly: a) Top view; b) Cross-section view of the joints

along the green line; c) Cross-section view of the joints along the red line; and d) An Xradia 520 is used for the

3D X-ray image.

40 Chip Scale Review January • February • 2022 [ChipScaleReview.com]

40