Page 39 - Chip Scale Review_January February_2022-digital

P. 39

A 2.2D die-last integrated substrate for heterogeneous

integration applications

By Dyi-Chung Hu [SiPlus Co.]

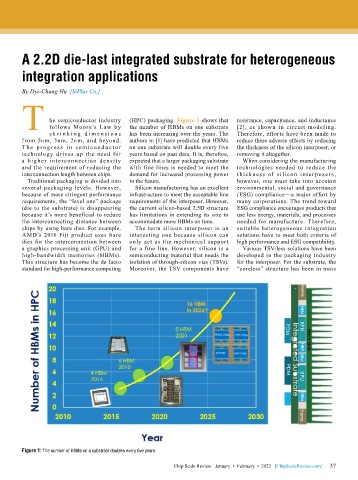

T he semiconductor industry (HPC) packaging. Figure 1 shows that resistance, capacitance, and inductance

follows Moore’s Law by

has been increasing over the years. The

Therefore, efforts have been made to

sh r i n k i n g d i m e n s i o n s the number of HBMs on one substrate [2], as shown in circuit modeling.

from 5nm, 3nm, 2nm, and beyond. authors in [1] have predicted that HBMs reduce these adverse effects by reducing

T h e p r og r e s s i n s e m ic o n d u c t o r on one substrate will double every five the thickness of the silicon interposer, or

technology drives up the need for years based on past data. It is, therefore, removing it altogether.

a higher intercon nection densit y expected that a larger packaging substrate When considering the manufacturing

and the requirement of reducing the with fine lines is needed to meet the technologies needed to reduce the

interconnection length between chips. demand for increased processing power thick ness of silicon inter posers,

Traditional packaging is divided into in the future. however, one must take into account

several packaging levels. However, Silicon manufacturing has an excellent environmental, social and governance

because of more stringent performance infrastructure to meet the acceptable line (ESG) compliance—a major effort by

requirements, the “level one” package requirements of the interposer. However, many corporations. The trend toward

(die to the substrate) is disappearing the current silicon-based 2.5D structure ESG compliance encourages products that

because it’s more beneficial to reduce has limitations in extending its size to use less energy, materials, and processes

the interconnecting distance between accommodate more HBMs on time. needed for manufacture. Therefore,

chips by using bare dies. For example, The term silicon interposer is an suitable heterogeneous integration

AMD’s 2016 Fiji product uses bare interesting one because silicon can solutions have to meet both criteria of

dies for the interconnection between only act as the mechanical support high performance and ESG compatibility.

a graphics processing unit (GPU) and for a fine line. However, silicon is a Various TSV-less solutions have been

high-bandwidth memories (HBMs). semiconducting material that needs the developed in the packaging industry

This structure has become the de facto isolation of through-silicon vias (TSVs). for the interposer. For the substrate, the

standard for high-performance computing Moreover, the TSV components have “coreless” structure has been in mass

Figure 1: The number of HBMs on a substrate doubles every five years.

37

Chip Scale Review January • February • 2022 [ChipScaleReview.com] 37