Page 10 - ChipScale_Jan-Feb_2020-digital

P. 10

Reliability and performance of wafer-level fan-out

packaging for automotive radar

By Walter Hartner, Martin Niessner, Francesca Arcioni, Markus Fink, Christian Geissler,

Gerhard Haubner, Maciej Wojnowski [Infineon Technologies AG]

A utomotive radar technology

at 77GHz for advanced

driver assistance systems

(ADAS) and autonomous driving requires

a package solution, which provides

both superior RF performance and

fulfills the strict automotive reliability

requirements. In the past, the automotive

industry used predominantly very mature

semiconductors and packages. Today,

however, a car will need to use the latest

packaging technology to provide the best

solution for ADAS sensors. One example

of this trend is the embedded wafer-level

ball grid array (eWLB) package. Infineon

was the first company to introduce

the eWLB package technology to the

automotive market in 2012 [1], only three

years after introducing this technology to

the consumer market [2].

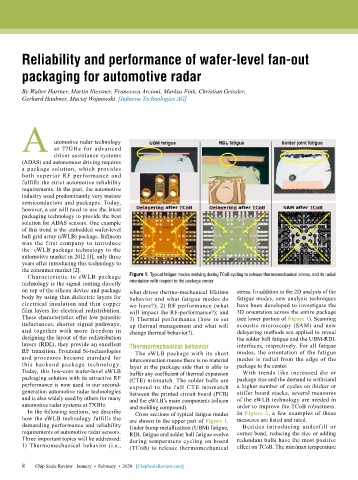

Characteristic to eWLB package Figure 1: Typical fatigue modes evolving during TCoB cycling to release thermomechanical stress, and its radial

technology is the signal routing directly orientation with respect to the package center.

on top of the silicon device and package what drives thermo-mechanical lifetime stress. In addition to the 2D analysis of the

body by using thin dielectric layers for behavior and what fatigue modes do fatigue modes, new analysis techniques

electrical insulation and thin copper we have?); 2) RF performance (what have been developed to investigate the

film layers for electrical redistribution. will impact the RF-performance?); and 3D orientation across the entire package

These characteristics offer low parasitic 3) Thermal performance (how to set (see lower portion of Figure 1). Scanning

inductances, shorter signal pathways, up thermal management and what will acoustic microscopy (SAM) and new

and together with more freedom in change thermal behavior?). delayering methods are applied to reveal

designing the layout of the redistribution the solder ball fatigue and the UBM-RDL

layers (RDL), they provide an excellent Thermomechanical behavior interfaces, respectively. For all fatigue

RF transition. Frontend Si-technologies The eWLB package with its short modes, the orientation of the fatigue

and processes became standard for interconnection means there is no material modes is radial from the edge of the

this backend package technology. layer at the package side that is able to package to the center.

Today, this low-cost wafer-level eWLB buffer any coefficient of thermal expansion With trends like increased die or

packaging solution with its attractive RF (CTE) mismatch. The solder balls are package size and the demand to withstand

performance is now used in our second- exposed to the full CTE mismatch a higher number of cycles on thicker or

generation automotive radar technologies between the printed circuit board (PCB) stiffer board stacks, several measures

and is also widely used by others for many and the eWLB’s main components (silicon of the eWLB technology are needed in

automotive radar systems at 77GHz. and molding compound). order to improve the TCoB robustness.

In the following sections, we describe Cross sections of typical fatigue modes In Figure 2, a few examples of those

how the eWLB technology fulfills the are shown in the upper part of Figure 1. measures are listed and rated.

demanding performance and reliability Under bump metallization (UBM) fatigue, Besides introducing underfill or

requirements of automotive radar sensors. RDL fatigue and solder ball fatigue evolve corner bond, reducing the size or adding

Three important topics will be addressed: during temperature cycling on board redundant balls have the most positive

1) Thermomechanical behavior (i.e., (TCoB) to release thermomechanical effect on TCoB. The min/max temperature

8 8 Chip Scale Review January • February • 2020 [ChipScaleReview.com]