Page 35 - ChipScale_Mar-Apr_2021-digital

P. 35

high production throughput to support

the GaN AuSn eutectic process. The

machines also support the AuSi eutectic

process by using different pre-heat

and eutectic temperatures and can be

configured to add epoxy dispensing and

epoxy stamping. Our fully-automated

solution for RF power amplifier device

manufacturing meets the challenges

posed by the accelerated deployment of

5G at an attractive return on investment

for users.

References

1. M. Di Paolo Emilio, “RF power

semiconductors for 5G shift to

WBG materials,” September 4,

2020, Electronic Products.

2. Mark LaPedus, “Power Amp Wars

Begin For 5G,” Aug. 24, 2020,

Semiconductor Engineering.

3. “GaN RF market applications,

players, technology, and substrates

2020,” Yole Développement report,

May 2020.

4. Paul Shepard, “Pressureless sinter

joining for next-gen GaN & SiC

power semis,” Sept. 01, 2017,

EEPower.

5. H. Yang, et al., “Improvement of

sintering performance of nanosilver

paste by tin doping, 22 Jan. 2020, J.

of Nanomaterials.

6. XiaominWang, et al., “Pressureless

sintering of nanosilver paste as

die attachment on substrates with

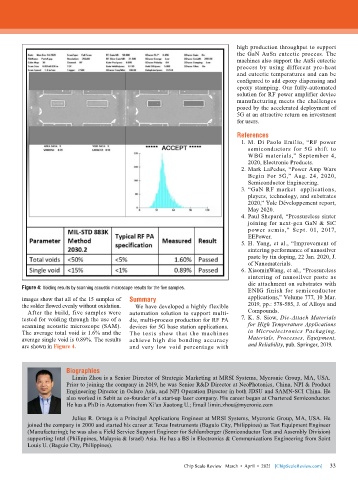

Figure 4: Voiding results by scanning acoustic microscope results for the five samples. ENIG finish for semiconductor

images show that all of the 15 samples of Summary applications,” Volume 777, 10 Mar.

the solder flowed evenly without oxidation. We have developed a highly flexible 2019, pp.: 578-585, J. of Alloys and

After the build, five samples were automation solution to support multi- Compounds.

tested for voiding through the use of a die, multi-process production for RF PA 7. K. S. Siow, Die-Attach Materials

scanning acoustic microscope (SAM). devices for 5G base station applications. for High Temperature Applications

The average total void is 1.6% and the The tests show that the machines in Microelectronics Packaging,

average single void is 0.89%. The results achieve high die bonding accuracy Materials, Processes, Equipment,

are shown in Figure 4. and very low void percentage with and Reliability, pub. Springer, 2019.

Biographies

Limin Zhou is a Senior Director of Strategic Marketing at MRSI Systems, Mycronic Group, MA, USA.

Prior to joining the company in 2019, he was Senior R&D Director at NeoPhotonics, China, NPI & Product

Engineering Director in Oclaro Asia, and NPI Operation Director in both JDSU and SAMN-SCI China. He

also worked in Sebit as co-founder of a start-up laser company. His career began at Chartered Semiconductor.

He has a PhD in Automation from Xi’an Jiaotong U.; Email limin.zhou@mycronic.com

Julius R. Ortega is a Principal Applications Engineer at MRSI Systems, Mycronic Group, MA, USA. He

joined the company in 2000 and started his career at Texas Instruments (Baguio City, Philippines) as Test Equipment Engineer

(Manufacturing); he was also a Field Service Support Engineer for Schlumberger (Semiconductor Test and Assembly Division)

supporting Intel (Philippines, Malaysia & Israel) Asia. He has a BS in Electronics & Communications Engineering from Saint

Louis U. (Baguio City, Philippines).

33

Chip Scale Review March • April • 2021 [ChipScaleReview.com] 33