Page 32 - Chip Scale Review_January February_2022-digital

P. 32

Managing trade-offs in the chiplet era

By Rob Munoz [Intel]

I n his famous 1965 paper [1]

Gordon Moore foreshadowed that

a chiplet-like approach would

become attractive. By chiplets, we mean

die that have been optimized to connect

to other die within the same packaged

device. Intel has used the term “tiles”

to describe chiplets that are integrated

using high-density, high-bandwidth

interconnects enabled by advanced

packaging technologies such as Intel’s

2.5D embedded multi-die interconnect

bridge (EMIB) [2], 3D Foveros [3], and

combined EMIB-Foveros (Co-EMIB)

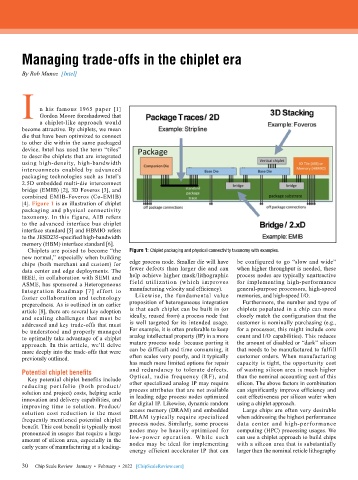

[4]. Figure 1 is an illustration of chiplet

packaging and physical connectivity

taxonomy. In this figure, AIB refers

to the advanced interface bus chiplet

interface standard [5] and HBMIO refers

to the JESD235-specified high-bandwidth

memory (HBM) interface standard [6].

Chiplets are poised to become “the Figure 1: Chiplet packaging and physical connectivity taxonomy with examples.

new normal,” especially when building

chips (both merchant and custom) for edge process node. Smaller die will have be configured to go “slow and wide”

data center and edge deployments. The fewer defects than larger die and can when higher throughput is needed, these

IEEE, in collaboration with SEMI and help achieve higher mask/lithographic process nodes are typically unattractive

ASME, has sponsored a Heterogeneous f ield utilization (which improves for implementing high-performance

Integration Roadmap [7] effort to manufacturing velocity and efficiency). general-purpose processors, high-speed

foster collaboration and technology Likewise, the fundamental value memories, and high-speed I/O.

preparedness. As is outlined in an earlier proposition of heterogeneous integration Furthermore, the number and type of

article [8], there are several key adoption is that each chiplet can be built in (or chiplets populated in a chip can more

and scaling challenges that must be ideally, reused from) a process node that closely match the configuration that the

addressed and key trade-offs that must is well targeted for its intended usage. customer is nominally purchasing (e.g.,

be understood and properly managed For example, it is often preferable to keep for a processor, this might include core

to optimally take advantage of a chiplet analog intellectual property (IP) in a more count and I/O capabilities). This reduces

approach. In this article, we’ll delve mature process node because porting it the amount of disabled or “dark” silicon

more deeply into the trade-offs that were can be difficult and time consuming, it that needs to be manufactured to fulfill

previously outlined. often scales very poorly, and it typically customer orders. When manufacturing

has much more limited options for repair capacity is tight, the opportunity cost

Potential chiplet benefits and redundancy to tolerate defects. of wasting silicon area is much higher

Key potential chiplet benefits include Optical, radio frequency (RF), and than the nominal accounting cost of this

reducing portfolio (both product/ other specialized analog IP may require silicon. The above factors in combination

solution and project) costs, helping scale process attributes that are not available can significantly improve efficiency and

innovation and delivery capabilities, and in leading edge process nodes optimized cost effectiveness per silicon wafer when

improving time to solution. Product/ for digital IP. Likewise, dynamic random using a chiplet approach.

solution cost reduction is the most access memory (DRAM) and embedded Large chips are often very desirable

frequently mentioned potential chiplet DRAM typically require specialized when addressing the highest performance

benefit. This cost benefit is typically most process nodes. Similarly, some process data center and high-performance

pronounced in usages that require a large nodes may be heavily optimized for computing (HPC) processing usages. We

amount of silicon area, especially in the low-power operation. While such can use a chiplet approach to build chips

early years of manufacturing at a leading- nodes may be ideal for implementing with a silicon area that is substantially

energy efficient accelerator IP that can larger than the nominal reticle lithography

30

30 Chip Scale Review January • February • 2022 [ChipScaleReview.com]