Page 54 - Chip Scale Review_November December_2021-digital

P. 54

effect as the coaxial spring socket, as well

as superior transmission characteristics

and low manufacturing cost.

High-frequency electrical

simulation analysis and verification

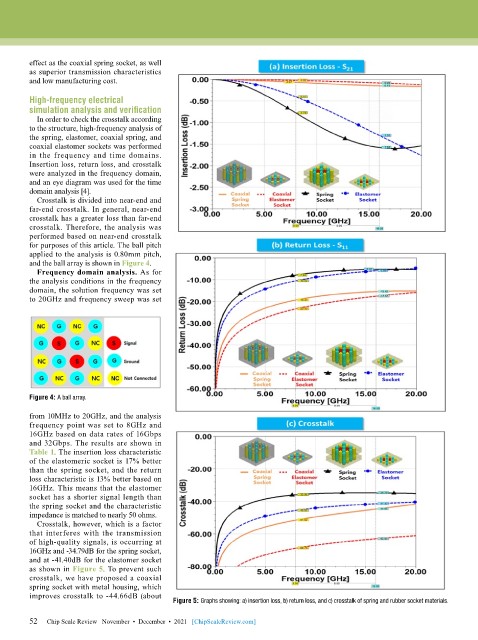

In order to check the crosstalk according

to the structure, high-frequency analysis of

the spring, elastomer, coaxial spring, and

coaxial elastomer sockets was performed

in the frequency and time domains.

Insertion loss, return loss, and crosstalk

were analyzed in the frequency domain,

and an eye diagram was used for the time

domain analysis [4].

Crosstalk is divided into near-end and

far-end crosstalk. In general, near-end

crosstalk has a greater loss than far-end

crosstalk. Therefore, the analysis was

performed based on near-end crosstalk

for purposes of this article. The ball pitch

applied to the analysis is 0.80mm pitch,

and the ball array is shown in Figure 4.

Frequency domain analysis. As for

the analysis conditions in the frequency

domain, the solution frequency was set

to 20GHz and frequency sweep was set

Figure 4: A ball array.

from 10MHz to 20GHz, and the analysis

frequency point was set to 8GHz and

16GHz based on data rates of 16Gbps

and 32Gbps. The results are shown in

Table 1. The insertion loss characteristic

of the elastomeric socket is 17% better

than the spring socket, and the return

loss characteristic is 13% better based on

16GHz. This means that the elastomer

socket has a shorter signal length than

the spring socket and the characteristic

impedance is matched to nearly 50 ohms.

Crosstalk, however, which is a factor

that interferes with the transmission

of high-quality signals, is occurring at

16GHz and -34.79dB for the spring socket,

and at -41.40dB for the elastomer socket

as shown in Figure 5. To prevent such

crosstalk, we have proposed a coaxial

spring socket with metal housing, which

improves crosstalk to -44.66dB (about

Figure 5: Graphs showing: a) insertion loss, b) return loss, and c) crosstalk of spring and rubber socket materials.

52

52 Chip Scale Review November • December • 2021 [ChipScaleReview.com]